ECOGEM flickerGUARD S9041TC2 FG - 10W

Dimmable 10 watt LED downlight, CRI90 with selectable CCT and flickerGUARD technology

Application

Ideal for any residential or commercial interior space, experiencing nuisance ripple induced flicker

Design Specifications

The innovative flickerGUARD Ecogem responds to both visual and non-visual harmonic induced flicker.

Trailing edge dimmable LED driver, with smooth dimming performance and flex and plug

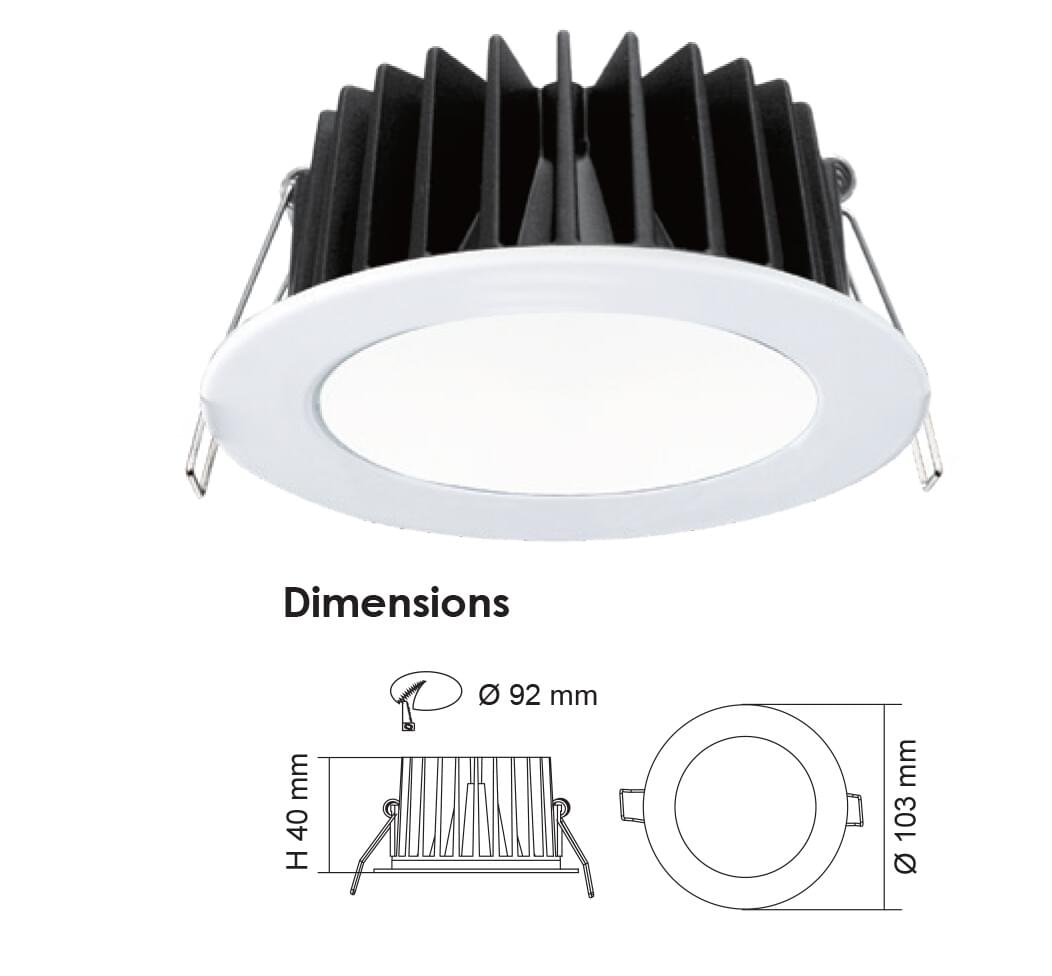

High efficiency LED optics with an opal polycarbonate diffuser

Selectable CCT 3000K / 4200K / 5700K, CRI>90

Durable Polyamide, reinforced aluminium body profile and white trim.

Colour trim options: Black (S9041 BK RING), Silver (S9041 SL RING), Satin Nickel (S9041 SN RING) IC - 4 rated, double insulated

Performance

- Dimmable - YES

- Dimmer Type - Trailing edge

(1) Due to continued product and technology enhancements, data sourced from sal.net.au shall not form part of any contract and or technical performance guarantee unless expressly confirmed in writing by SAL at the time of order. (2) Products are sold in accordance with SAL Terms and Conditions of sale and all images shown are for illustration purposes only and may vary from the actual colour or finish. (3) Unless specifically stated, all Interior product IP ratings nominated are from "below the ceiling". IC ratings (if any) apply to the downlight only. (4) VEET, IPART & REES approval validation must only be sourced via the dedicated web listed catalogues; icons shown (if any) on the relevant product page are a guide only and do not guarantee approvals for individual models. (5) With the exception of DIY lamps, all other products must be installed by a qualified electrical installer.

With over 1000 Australian trade partners, finding where to buy SAL products is easy. Search a trade partner nearby